The most common systems for transmitting power from a drive to a driven shaft are belt gear and. Heavy-duty V-belt for good slip control and noiseless clutch engagement.

Flat Belt Drive Types Advantage And Disadvantage Mecholic

Select standard v-belt cross section from PSG 758 based on motor power kW Step1.

. B Type V-belts with a top width of 2132 inches. See reviews photos directions phone numbers and more for Industrial V Belts locations in Piscataway NJ. I am designing a piece of equipment that will be mounted onto the forks of a forklift.

150 kW at speeds of 16000 ftmin. Sep 3 2013 1 Im working on my IH LA lawn tractor project. Figure 5 Metric V-belt Profiles.

Nominal Dimensions of V-belt Cross Sections in mm Classical V-Belts 01 Cross Section W H α Features 125 16. The following article provides an overview of V-belts outlining their operating principles the types available and their design and selection. Ad But Did You Check eBay.

The helical offset tooth design forms a chevron pattern and causes the teeth to engage progressively. C Type V-belts with a top width of 78 inches. We Have Almost Everything On eBay.

As the manufacturer of the full line of power transmission belts Continental offers a variety of friction-fit drive elements for wraparound drives in which slip is permissible. They test to design a clutch kit and belt combination that will operate at an acceptable temperature while providing the most aggressive upshift and backshift possible. The first and second pulley halves 9 and 10 of mechanical clutch 110 are configured to engage the v-belt of a v-belt system riding on a ball bearing 7 positioned between the two pulley halves.

D Type V-belts with a top width of 1 14 inches. In this video I show you how I built my manual v-belt clutch mechanism for my lumber mill. How much power do you need to transmit and at what speed.

Check out our design belt clutch selection for the very best in unique or custom handmade pieces from our shops. Design For uniform wear w is constant so PV is constant. This heavy-duty clutch is designed for go-karts.

Conditionally resistant to oil resistant to temperatures from -30C to 80C dust. The fractional horsepower V-belt profile is designed for light-duty applications such as lawnmowers snow blowers attic or furnace fans etc. Clutches Intermittent Service 3-5 Hours Daily or Seasonal Normal Service 8-10 Hours Daily Continuous Service 16-24 Hours.

Flex Belts Truly Endless. V Belt Selection - Using PSG Design Data Book. Dimensions of V-belts and pulleys together with basic design data are covered in this manual.

Locations Manufacturer 10 - 249 Mil 1951 100-199. And the lack of clutch action. Bore with a 7 HP rating.

Customer needs a V-belt drive for an agitator that is in operation continuously. Step 1Define the rated power for drivinIn v-belt systems there is always a. There are other choices at our dealer.

- Diameter of larger pulley mm - Speed of the larger pulley rpm Calculate the diameters of the smaller and larger pulley using the relation. If you want to use a belt drive on your cart this is the solution. V belt clutch design help.

V-belt drives permit large speed ratios and provide long life. V-belts as adjustable brakeclutch. First pulley half 9 is fixed to the end of a longitudinal shaft 1 shown and described in further detail below with reference to FIG.

Specially developed for machines used in garden and park upkeep Properties. This V-Belt Clutch is a 34in. The original clutch setup was missing.

Step 2Determine the design power froIf you have the power information oStep 3Standard V-belt selection. Many of my friends have been asking me how I made the clutch this short video is showing how easy to do it should be a flat belt pulley and steel L-shape. The Initial classical V design replaced leather belts by taking over their applications in a wide range of industries such as agriculture ventilation and industrial machinery.

Variable speed belts just like timing belts have their. This manual does not apply to automotive and agricultural drives. The tractor already had a kludged together motor and drive setup on it when I got it that did not really work.

Polytech Design Inc manufacturer distributor of timing belts pulleys Clifton NJ. Belts with Covers and Backings. Check Out Clutch V Belt On eBay.

Jdunfee5 Mechanical OP 20 Aug 15 1542. Pulleys Bar Stock Flanges. Available as air engaged straight bore shaft mounted clutches with sealed bearings 100 in.

For example Classical V cog belt will be 3VX 5VX etc. Narrow V-belts however will operate up to 10000 ftmin 50 ms. Open End Belt Rolls.

Belt Drive Go Kart. Made in the USA. What is unusual is that we also want the ability to lift it up and then.

Start date Sep 3 2013. The v-belt drive gives compactness due to the small distance between the centres of pulleys. It will pick up a long item horizontally and either rotate it 180 deg or take it to a vertical position.

Setting p P and V rw the maximum pressure p a occurs where r is minimum r d2 Uniform Wear Shigleys Mechanical Engineering Design Find the total normal force by letting r vary from d2. Self Tracking Belts with V-Guide. Manufacturer of industrial linear motion products components including V-belt clutches.

They are easily installed and removed quiet and low maintenance. It is a centrifugal clutch which engages a V-belt. Looking For Clutch V Belt.

Since the v-belt are made endless and there is no trouble therefore the drive is smooth. 5 Hp 900 RPM Outer Datum Diameter 30. Conventional V-belt is the most common V-belt type and has been around the longest.

EPI has developed CVT performance clutch kits for 20 years and they consider the belt an important part of the kit. How to Measure a V-Belt. Nominal dimensions of the four cross sections are given in Table 1.

These belts have a thinner cross-section and lighter gauge tensile cord Figure 6 making them more flexible and able to bend around small sheaves. E Type V-belts with a top width of 1 12 inches. The drive is positive because the slip between the belt and the pulley groove is negligible.

V-belt clutches are available in bore sizes of 0625 in 1 to 3 V groove styles. Initial Selection adn Design COnsideration V-Belt Application. Joined Spliced and Welded Endless.

V-belt selection its a veritable cinch. Belts Clutches and Brakes. It provides longer life 3 to 5 years.

EPI introduced its first Severe Duty line of belts in 2007. Wrapped V-belts for harsh ambient conditions raw-edge V-belts for maximum power transmission and serpentine drives or variable-speed belts for variable. You need to select a standard v-bel.

Timing belts with a helical offset tooth design are available.

Go Kart Guru Go Kart Clutches Which Kind Should I Use

What Is Belt Drive Types And Material Of Belt Engineering Choice

How V Belt Clutch Works X2f My Little Homemade Garden Tractor Part5 Youtube Tractors Garden Tractor Homemade Tractor

Alternator Pulley Design And Function A Little Basic Information Metroplex Alternator Starter

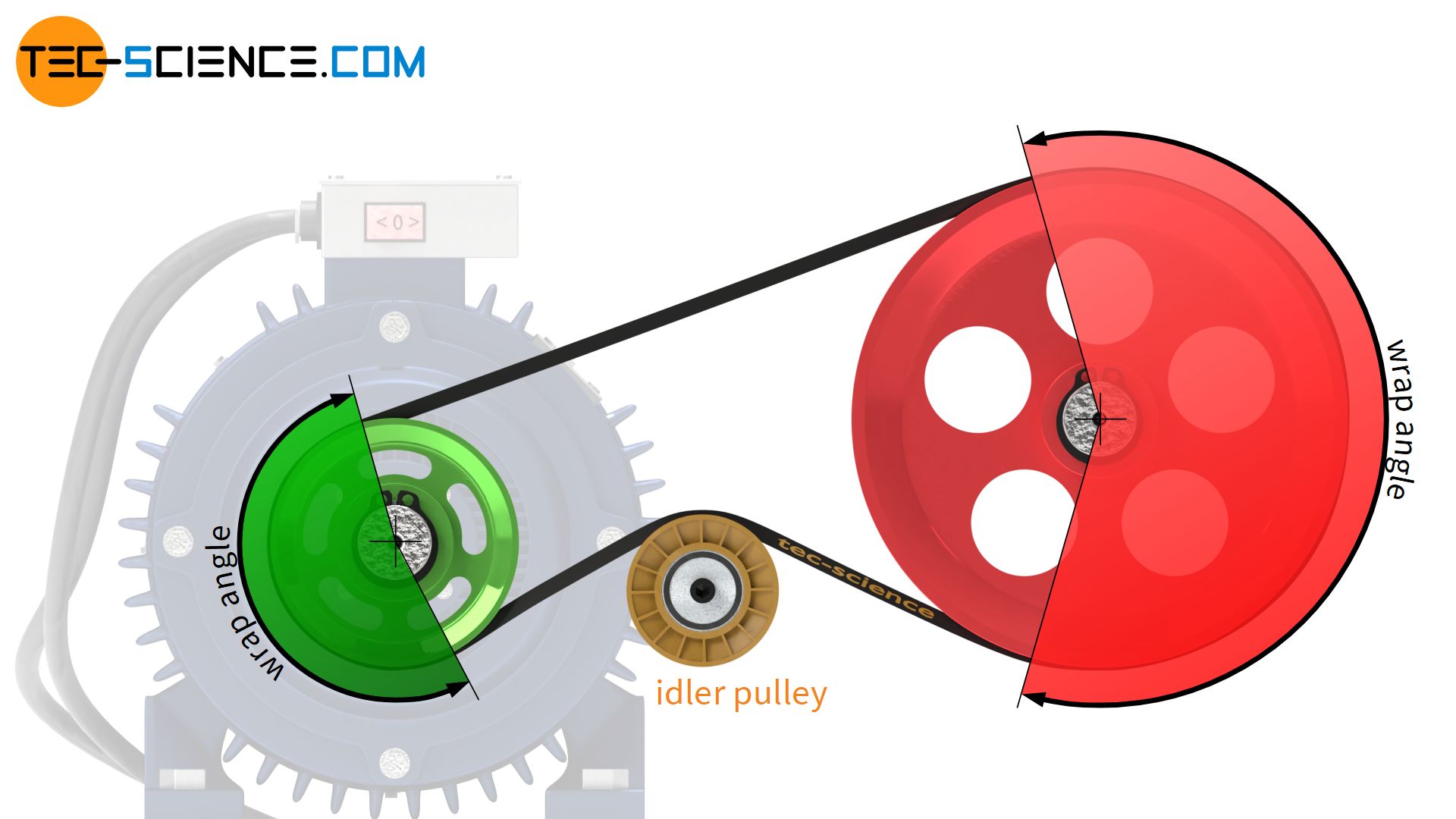

How Does A Belt Drive Work Tec Science

0 comments

Post a Comment